ASTM E165 Testing of Liquid Penetrants

This is one of our most basic inspection techniques, but it’s also one of our most effective non-destructive testing methods. Contact us right now for dependable results and knowledgeable guidance from a friendly engineer. We provide coverage throughout the United Kingdom. A penetrating dye solution is applied to the required surface area of the investigated […]

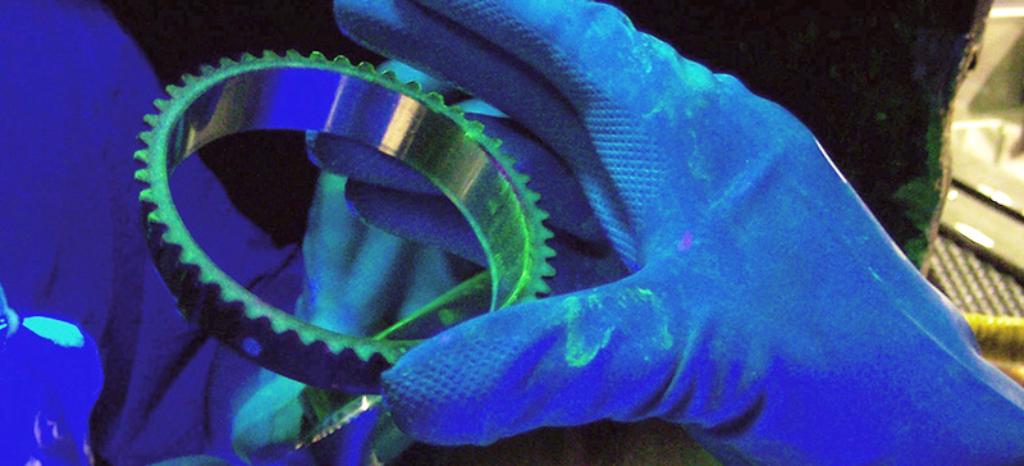

APPLICATION OF A FLUORESCENT PENETRANT SYSTEM IN 5 STEPS

It is difficult to find surface fractures on a non-porous substance with the naked eye. This is where tools like a fluorescent penetrant system and custom NDT equipment are useful. The techniques are used to find flaws in objects made of ceramic, metal, and plastic, including leaks and cracks. The steps you must follow to […]

Liquid Penetrant Inspection

The term “liquid penetrant inspection,” or “LPI,” also refers to dye penetration testing. One of the non-destructive inspection methods most frequently employed is dye penetrant examination. It may be utilised in a huge range of product applications and sectors. This approach is employed in metalworking facilities, the aerospace industry, the production of electrical energy, and […]

ISO9712-2022 UPDATES AND REQUIREMENTS, Are you ready?

We’ve all been waiting, we heard it was coming. And many of those affected will now know that its arrived, what are we talking about? It’s called ISO9712-2022 the International standard for qualification and certification of NDT personnel affective for General engineering sectors and manufacturing. There are several factors to address which may have impact […]

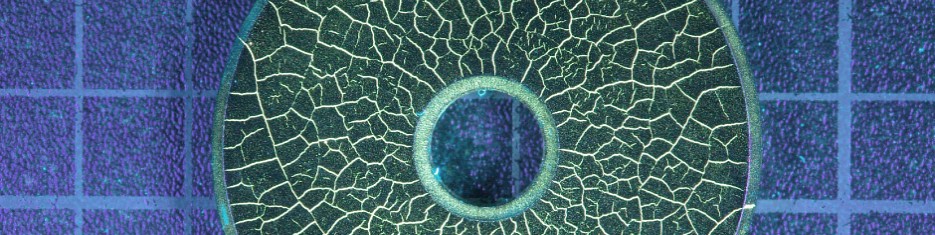

PSM-5 TAM Panel Recommended Care & Maintenance

The PSM-5 simulated defect panel has become the industry standard for repeated function of a company’s Liquid penetrant process, utilised commonly with fluorescent systems monitoring daily performance and aiding to fault find the defective element of the system wherever monitoring would fall below an established baseline. The PSM-5 panel is manufactured from stainless steel sheet […]

Penetrant Colour and Fluorescent Brightness

Penetrant Colour and Fluorescence The colour of the penetrant material is of obvious importance in a visible dye penetrant inspection, as the dye must provide good contrast against the developer or part being inspected. Remember from the earlier discussion of contrast sensitivity that generally the higher the contrast, the easier objects are to see. The […]

Penetrant Testing Materials

The penetrant materials used today are much more sophisticated than the kerosene and whiting first used by railroad inspectors near the turn of the 20th century. Today’s penetrants are carefully formulated to produce the level of sensitivity desired by the inspector. To perform well, a penetrant must possess several important characteristics. A penetrant must: Spread […]

Defect Types Found During Non-Destructive Testing

The following is a non-exhaustive list of some of the defect types which can be found during the non destructive testing process. CASTING DEFECTS The following defects are present in the material before any further processing operations such as forging, or rolling have begun. All casting defects are therefore inherent. Porosity This is formed […]

Etching of Components Prior to Penetrant Testing

As the nature of penetrant testing is to locate surface breaking defects this means that the preparation of the surface is one of the most critical parts of the entire penetrant testing operation. With this in mind many specifications and end users feel the need to specify pre penetrant etching of parts which have been […]